Rebound Hammer test

Conducting a rebound hammer test as per IS 13311(Part-2), ASTM C 805. The rebound hammer test shall be conducted at all those points were the UPV test has been performed. One point consisting of six readings spread over an area of 1 sq. shall be considered as 1 test.

OBJECTS

The rebound hammer method could be used for :

- Assessing the compressive strength of concrete with the help of suitable co-relations between rebound index and compressive strength

- Assessing the uniformity of the concrete

- Assessing the quality of concrete in relation to the standard requirements

- Assessing the quality of one element of concrete in relation to another.(1)

Principle of test: The test is based on the principle that the rebound of an elastic mass depends on the hardness of the surface upon which it impinges. When the plunger of the rebound hammer pressed against the surface of the concrete, the spring controlled mass rebounds and the extent of such rebound depend upon the surface hardness of concrete. The surface hardness and therefore the rebound is taken to be relation to the compressive strength of concrete. The rebound is read off along a graduated scale and is designated as the rebound number or rebound index.

Basic Features of Rebound Hammer

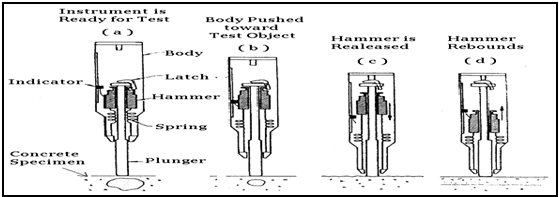

Working of rebound hammer: A schematic cut way view of schmidt rebound hammer is shown in fig. 1. The hammer weight about 1.8 kg., is suitable for use both in a laboratory and in the field. When the plunger of rebound hammer is pressed against the surface of concrete, a spring controlled mass rebounds and the extent of such rebound depends upon the surface hardness of concrete.

The rebound distance is measured on a graduated scale and is designated as rebound number. Basically, the rebound distance depends on the value of kinetic energy in the hammer, prior to impact with the shoulder of the plunger and how much of that energy is absorbed during impact. The energy absorbed by the concrete depends on the stress-strain relationship of concrete. Thus, a low strength low stiffness concrete will absorb more energy than high strength concrete and will give a lower rebound number.

Fig.2 :

Schematic Cross Section of Rebound Hammer & Principle of Operation

Depending upon the impact energy, the hammers are classified into four types i.e. N, L, M & P. Type N hammer having an impact energy of 2.2 N-m and is suitable for grades of concrete from M-15 to M-45. Type L hammer is suitable for lightweight concrete or small and impact sensitive part of the structure. Type M hammer is generally recommended for heavy structures and mass concrete. Type P is suitable for concrete below M15 grade.

Method of testing (operation)

- To prepare the instrument for a test, release the plunger from its locked position by pushing the plunger against the concrete and slowly moving the body away from the concrete. This causes the plunger to extend from the body and the latch engages the hammer mass to the plunger rod.

- Hold the plunger perpendicular to the concrete surface and slowly push the body towards the test object. (The surface must be smooth, clean and dry and should preferably be formed, but if trowelled surfaced are unavoidable, they should be rubbed smooth with the carborundum stone usually provided with the equipment. Loose material can be ground off, but areas which are rough from poor compaction, grout loss, spalling or tooling must be avoided, since the results will be unreliable).

- As the body is pushed, the main spring connecting the hammer mass to the body is stretched. When the body is pushed to the limit, the latch is automatically released and the energy stored in the spring propels the hammer mass towards the plunger tip. The mass impacts the shoulder of the plunger rod and rebounds.

- During rebound, the slide indicator travels with the hammer mass and records the rebound distance. A button on the side of the body is pushed to lock the plunger in the retracted position and the rebound number is read from the scale.

The test can be conducted horizontally, vertically upward or downward or at any intermediate angle. Due to different effects of gravity on the rebound as the test angle is changed, the rebound number will be different for the same concrete. This will require separate calibration or correction charts, given by the manufacturer of the hammer.